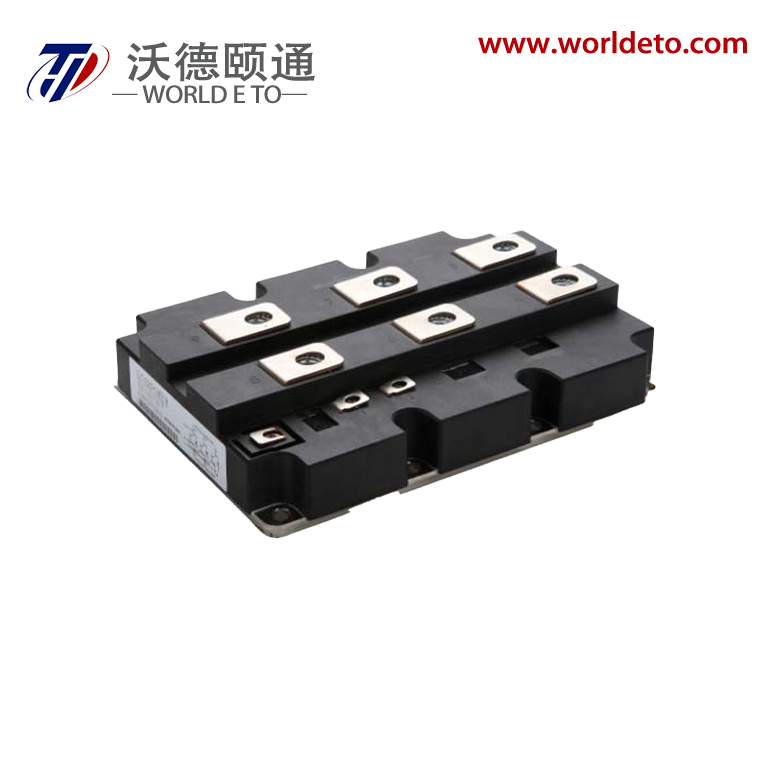

servo drive controller

Un controller per azionamenti servo è un dispositivo elettronico sofisticato che regola con precisione la posizione, la velocità e la coppia dei motori servo nei sistemi automatizzati. Questo avanzato sistema di controllo si integra perfettamente con varie applicazioni industriali, offrendo un'elevata precisione e affidabilità nelle operazioni di controllo del movimento. Il controller elabora segnali di feedback provenienti da encoder o resolver, confrontando la posizione reale con quella desiderata per mantenere un movimento accurato. Funziona attraverso un sistema di controllo a ciclo chiuso, aggiustando continuamente i parametri del motore per ottenere prestazioni ottimali. I moderni controller per azionamenti servo sono dotati di capacità di elaborazione dei segnali digitali, che permettono regolazioni in tempo reale e profili di movimento complessi. Supportano diversi protocolli di comunicazione, consentendo l'integrazione con PLC, reti industriali e sistemi di automazione. Questi controller offrono curve di accelerazione/decelerazione programmabili, avanzate funzionalità diagnostiche e funzioni protettive per garantire un'operazione sicura. Le loro applicazioni spaziano tra numerosi settori industriali, dai macchinari CNC e robotica fino ad equipaggiamenti per il confezionamento e sistemi di produzione precisa.