igbt induction heater

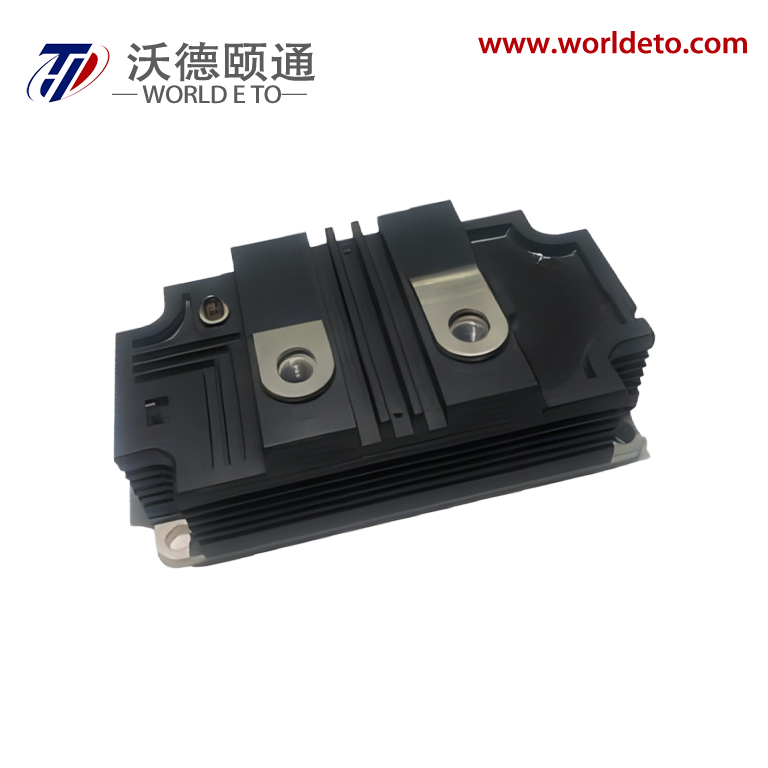

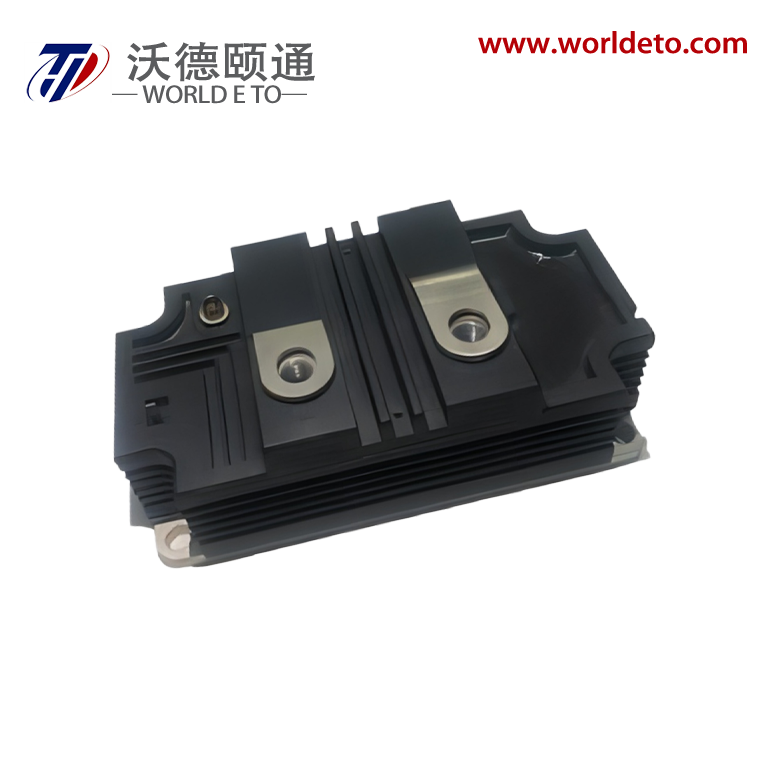

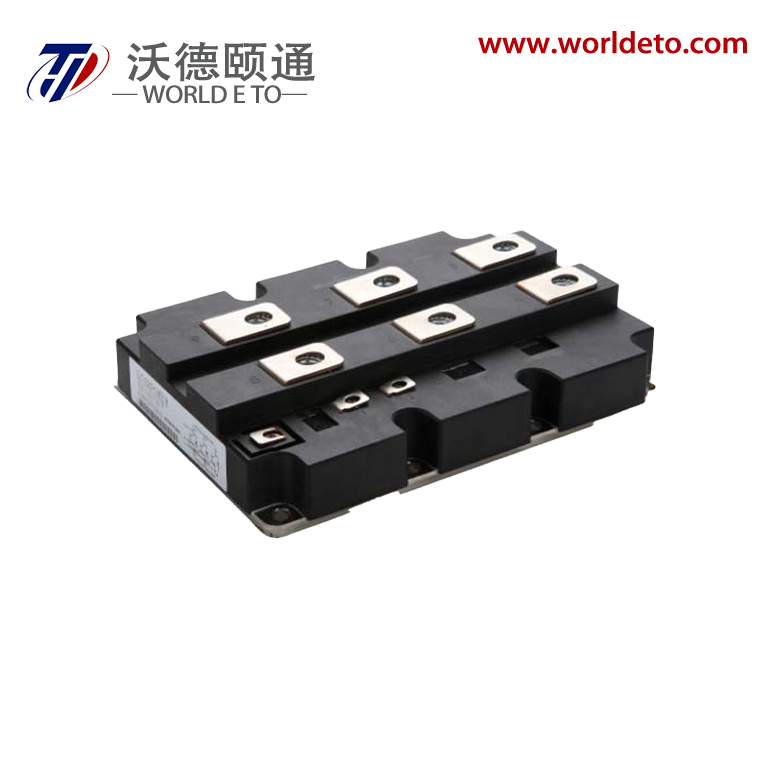

The IGBT induction heater represents a cutting-edge advancement in heating technology, combining precision control with efficient power delivery. This sophisticated heating system utilizes Insulated Gate Bipolar Transistor (IGBT) technology to generate electromagnetic fields that produce rapid and uniform heating in conductive materials. Operating at high frequencies, typically between 20kHz and 100kHz, these heaters create eddy currents within the target material, resulting in efficient heat generation without direct contact. The system comprises several key components, including the IGBT power supply, work coil, cooling system, and control interface. Its microprocessor-controlled operation enables precise temperature regulation and power output adjustment, making it ideal for various industrial applications. The technology excels in heat treating, brazing, soldering, and metal hardening processes, offering unprecedented control over heating parameters. The system's ability to deliver concentrated heat to specific areas while maintaining energy efficiency has made it invaluable in manufacturing, automotive, and metallurgical industries. Modern IGBT induction heaters incorporate advanced safety features, including overload protection, temperature monitoring, and emergency shutdown systems, ensuring reliable and secure operation in industrial environments.