Introduction: The Pivotal Role of IGBT Modules in EV Technology

IGBT modules are vital components in electric vehicles, contributing significantly to their functionality and efficiency. As environmental concerns escalate globally, there is a growing emphasis on EV technology as a sustainable energy solution. This shift highlights the importance of improving various systems within electric vehicles—a feat accomplished by the efficient regulation offered by IGBT modules. These modules facilitate enhanced performance by optimizing energy conversion and power management, key elements that drive advancements in EV technologies. By improving motor drive and battery management systems, IGBT modules ensure efficient energy usage and a superior driving experience, ushering in a new era in electric transportation.

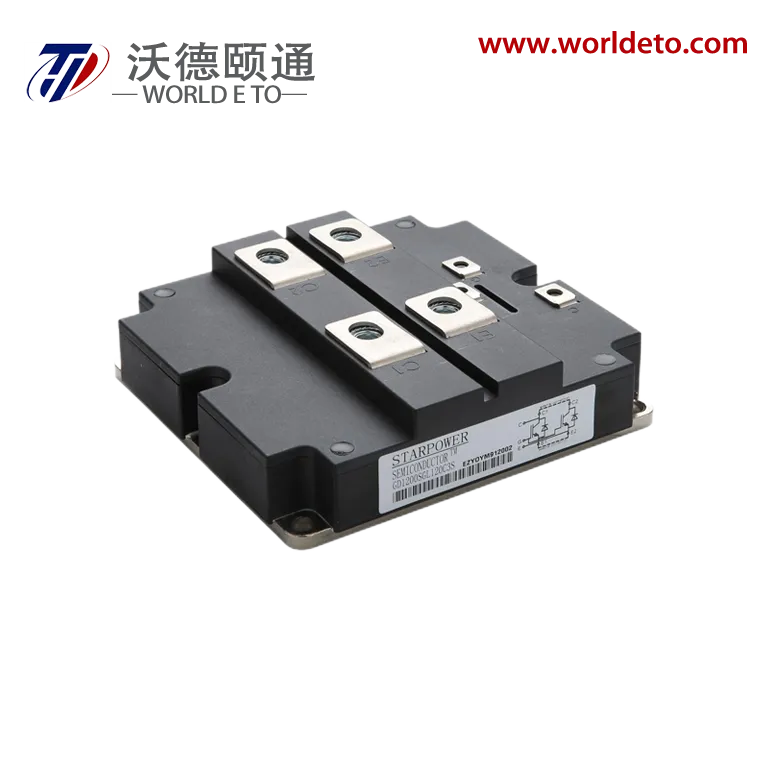

Core Functions of IGBT Modules in Electric Vehicles

Power Conversion: Bridging DC Batteries to AC Motors

IGBT modules play a pivotal role in electric vehicles by efficiently converting DC (direct current) electricity from the vehicle's battery into AC (alternating current) needed to power the electric motor. This conversion process is crucial as it ensures the motor receives the appropriate current type to function. Modern IGBT modules are known for their high efficiency in power conversion, achieving rates of up to 95%. Such efficiency not only maximizes energy utilization but also reduces energy loss during the conversion process, contributing to the overall energy efficiency of electric vehicles.

Motor Control: Precision and Efficiency in Traction Systems

Beyond power conversion, IGBT modules significantly enhance the precision of motor control systems in electric vehicles. This precision allows for smoother acceleration and deceleration, delivering a more refined driving experience. The impact on traction control systems is profound, as precise motor control ensures efficient power distribution to the wheels. This results in better handling and performance under various driving conditions, offering drivers improved safety and confidence, whether navigating urban streets or challenging terrains.

Thermal Management Integration in Power Electronics

Thermal management is another critical function facilitated by IGBT modules. As power electronics in electric vehicles generate significant heat, managing this thermal energy is vital to maintaining system reliability and longevity. Innovations in thermal management have led to improved performance and reduced risks of overheating, which can otherwise lead to component failure. Advanced heat dissipation techniques, such as the use of direct-cooling wave baseplates, are central to enhancing the thermal management capabilities of IGBT modules, ensuring they maintain optimal operation even under high-load conditions.

Key Benefits of IGBT Modules for Electric Vehicles

Enhanced Energy Efficiency in Drivetrain Systems

IGBT modules play a vital role in enhancing the energy efficiency of electric vehicle (EV) drivetrain systems. These components reduce overall energy consumption, making EVs more economical and environmentally friendly. Studies have shown that the integration of IGBT modules can lead to significant energy savings by optimizing power management within the vehicle. This efficiency is particularly crucial as it helps in extending the lifespan of the battery and reduces the frequency of charging, contributing to the practicality and appeal of electric vehicles.

Reduced Switching Losses for Extended Range

IGBT modules are crucial in minimizing switching losses, thereby extending the driving range of electric vehicles. By efficiently managing power conversion, these modules enhance the vehicle's performance, allowing it to travel further on a single charge. Advanced IGBT technology has been reported to improve the driving range by up to 10%, offering a significant advantage to consumers seeking longer and more reliable travels in their EVs. This reduction in energy loss is key to optimizing battery usage and ensuring that vehicles operate at peak performance levels.

Compact Design for High Power Density

The compact design of IGBT modules enables higher power densities, a critical factor in the design of electric vehicles. This is particularly beneficial as it allows for more efficient use of space within the battery compartments, which is a major consideration in EV design. Manufacturers have provided evidence that these IGBT modules save space and facilitate the integration of additional components without compromising performance. Such space optimization supports the ever-increasing demand for sleeker, more powerful electric vehicles and aids in maintaining a balanced weight-to-power ratio.

IGBT Modules' Impact on EV Performance Metrics

Acceleration Improvements Through Faster Switching

Faster switching times in IGBT modules significantly enhance acceleration in electric vehicles, driving notable performance improvements. By enabling rapid power modulation, these modules decrease the time required for EVs to accelerate from 0 to 60 mph. Industry benchmarks illustrate how vehicles equipped with advanced IGBT technology achieve superior acceleration, thus beating traditional propulsion systems in tests. For instance, Infineon's EDT2 generation IGBTs exhibit optimal switching characteristics, boosting drivetrain responsiveness and efficiency. The ability to handle high switching frequencies contributes to minimized energy loss and maximized torque delivery, resulting in stellar acceleration benchmarks.

Optimizing Battery Life with Efficient Power Regulation

IGBT modules excel in facilitating efficient power regulation, pivotal for extending the battery life of electric vehicles. These modules intelligently modulate power flow to the drivetrain, minimizing unnecessary electricity consumption, thereby conserving battery life. Data underscores the improvement in battery lifespan when optimized power use strategies are employed, showcasing how IGBT integration can deter battery depletion. Infineon's EDT2 technology, characterized by reduced light load power losses, exemplifies this efficiency. With such innovations, EV manufacturers can provide vehicles that not only last longer but also offer consistent performance over extended periods.

Enabling Higher Voltage Architectures (750V-1200V)

The shift towards higher voltage architectures, ranging from 750V to 1200V, is a compelling trend enabled by IGBT technology in electric vehicles. This transition promises numerous performance benefits, such as enhanced power efficiency and reduced energy dissipation. IGBT modules allow for robust handling of these high-voltage systems, ensuring reliability and improved thermal management. Operating at higher voltages contributes to the reduction of current flow, which subsequently decreases I^2R losses. Thus, adopting high-voltage architectures through IGBT modules translates into superior energy savings and vehicle performance, firmly establishing them as a preferred choice in modern EV design.

Challenges and Innovations in IGBT Implementation

Heat Dissipation in High-Power Applications

Heat generation poses a significant challenge in high-power IGBT applications, particularly within electric vehicles (EVs), where efficient thermal management is crucial to maintain performance and reliability. Excessive heat can lead to reduced efficiency and potential failure of the IGBT modules, affecting the overall vehicle performance. Innovations in heat management, such as enhanced thermal interfaces and advanced cooling techniques, are being developed to address these issues. For instance, integrating thermal barriers and employing high-conductivity materials in IGBT packaging help dissipate heat more effectively, ensuring stable operation of EVs even under demanding conditions.

Size Constraints vs. Power Demands

Balancing the size constraints of IGBT modules with the rising power demands of modern EVs is an ongoing challenge for manufacturers. The compact design of EVs necessitates that components, including IGBT modules, be as small as possible yet powerful enough to handle the energy requirements efficiently. To address this, innovations like miniaturized high-power density modules utilize cutting-edge materials and designs. For example, wide-bandgap materials such as Silicon Carbide (SiC) are being employed to develop smaller, more efficient IGBTs that meet both size and power specifications, enhancing the integration and performance of power electronics in EVs.

Advanced Cooling Solutions: Pin-Fin and Liquid Cooling

Advanced cooling technologies, like pin-fin heat sinks and liquid cooling systems, are essential for enhancing the thermal performance of IGBT modules in EVs. Pin-fin heat sinks provide an increased surface area for heat dissipation, offering superior thermal management compared to traditional cooling methods. Meanwhile, liquid cooling systems efficiently transfer heat away from IGBTs, maintaining optimal temperatures under high-power operation. Case studies have shown significant improvements in thermal performance with these solutions, enabling IGBT modules to operate at higher efficiencies and reliability levels. As EVs push for more power and efficiency, such innovations will play a crucial role in overcoming thermal challenges.

Conclusion – The Future of IGBT Modules in EVs and Automotive Electronics

IGBT modules are set to play a transformative role in the future of electric vehicles, offering profound impacts on performance and efficiency. These modules, by effectively managing energy conversion, not only boost the power efficiency of EVs but also enhance their overall environmental sustainability. The continuous development of IGBT technology could lead to further miniaturization and higher efficiency standards, paving the way for more compact powertrain designs and potentially reducing production costs.

Looking ahead, advancements in IGBT modules may drive groundbreaking changes in EV design and functionality. With innovations like direct water cooling and compact module structures, manufacturers are consistently focusing on overcoming existing technical challenges. For instance, future trends may revolve around further size reduction and loss minimization, as seen with Fuji Electric's development of a direct liquid cooling thin IGBT module. As technology progresses, the integration of sensors for precise temperature and current detection may become standard, ensuring enhanced safety and performance in automotive electronics. The trajectory of IGBT modules is undoubtedly geared towards elevating the future of mobility solutions.

FAQ Section

What are IGBT modules, and why are they important in electric vehicles?

IGBT modules, or Insulated Gate Bipolar Transistors, are crucial components in electric vehicles. They play a significant role in power conversion, efficiently converting DC from the vehicle's battery to AC necessary for the electric motor. This ensures efficient energy usage and better vehicle performance.

How do IGBT modules improve the energy efficiency of electric vehicles?

IGBT modules enhance energy efficiency by optimizing power management within electric vehicles. They reduce switching losses, which helps extend the driving range, make better use of battery power, and ultimately lower energy consumption.

What advancements are being made in IGBT technology?

Current advancements in IGBT technology focus on reducing size while increasing power density and efficiency. Developments such as using wide-bandgap materials like Silicon Carbide, and innovations in thermal management, contribute to better performance and more compact designs.

Table of Contents

- Introduction: The Pivotal Role of IGBT Modules in EV Technology

- Core Functions of IGBT Modules in Electric Vehicles

- Key Benefits of IGBT Modules for Electric Vehicles

- IGBT Modules' Impact on EV Performance Metrics

- Challenges and Innovations in IGBT Implementation

- Conclusion – The Future of IGBT Modules in EVs and Automotive Electronics

- FAQ Section