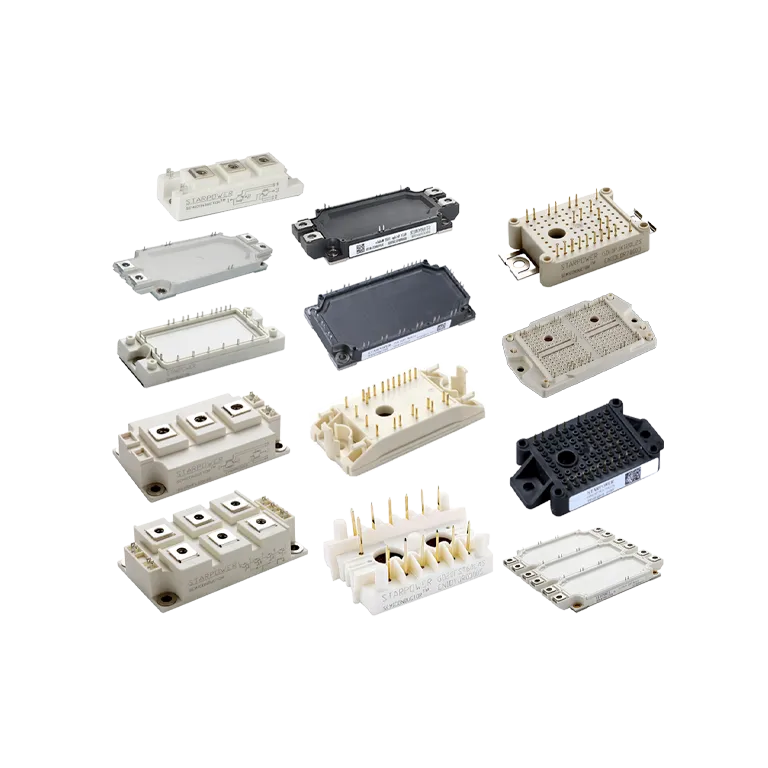

IGBT modules, or Insulated Gate Bipolar Transistors, are integral components in power electronics, playing a pivotal role in the efficient switching and control of electrical power. These devices combine the high efficiency and fast switching of MOSFETs with the high-current and low-saturation-voltage capability of bipolar transistors, making them ideal for handling large power levels. As demand for renewable energy systems and electric vehicles continues to soar, the role of reliable IGBT modules in modern power systems becomes increasingly vital. They ensure that power systems operate smoothly and efficiently, supporting the transition to more sustainable energy solutions. Understanding the significance of these modules paves the way for improved design and maintenance practices. By focusing on their reliability and optimal performance, industries can enhance both the lifespan and efficiency of their systems.

Common Failure Conditions of IGBT Modules

IGBT modules are critical in modern power electronics, yet they're prone to specific failure conditions that can drastically affect their performance. Understanding these conditions helps in preventing failures and improving module reliability.

Thermal Runaway in IGBT Modules

Thermal runaway is a severe failure condition in IGBT modules characterized by an uncontrollable temperature increase that can damage or destroy the module. This peril often arises due to inadequate cooling systems and poor thermal management practices. Effective heat dissipation strategies are crucial in this context, as studies indicate that over 50% of IGBT failures are attributable to thermal runaway. Such statistics underscore the importance of incorporating robust thermal management in module design and maintenance to avert catastrophic failures.

Overvoltage Stress and Breakdown

Overvoltage stress can critically affect IGBT modules by leading to the breakdown of the gate oxide, resulting in catastrophic failure. This issue typically occurs due to voltage transients and surges, necessitating the implementation of robust voltage protection mechanisms to safeguard the modules. Research shows that employing snubber circuits can significantly mitigate voltage-induced failures, reducing the incidence by approximately 40%. This highlights the need for effective voltage transient protection to ensure IGBT module longevity.

Short-Circuit Failures

Short-circuit failures in IGBT modules occur when there's an unintended path for excessive current, potentially causing irreversible damage. The rapid current spike can exceed the module’s ratings, making protective circuitry essential to prevent such occurrences. Industry statistics suggest that around 30% of IGBT failures arise from short-circuit events, emphasizing the need for vigilant monitoring and effective failure protection strategies in power electronic systems. Implementing these safeguards is vital for maintaining the operational integrity of IGBT modules and reducing failure rates.

Identifying IGBT Module Failures

Overheating Indicators and Thermal Monitoring

Thermal monitoring is essential for detecting overheating, a significant precursor to IGBT module failure. Utilizing modern tools such as infrared thermography and temperature sensors can effectively identify hot spots that may develop within the modules. Studies suggest that by implementing regular thermal monitoring, the efficiency of preventive maintenance programs can be improved by up to 70%. This proactive approach allows for early intervention, potentially preventing costly downtimes and extending the lifespan of the modules.

Electrical Arcing and Insulation Degradation

Electrical arcing is a warning sign of insulation degradation, often indicating a compromise in the module's protective barriers. It is crucial to conduct visual inspections to look for burn marks and listen for unusual sounds that may signify arcing. By adhering to stringent insulation testing protocols, the risk of failure can be significantly reduced, maintaining the dielectric integrity of the module. This approach ensures that the module's protective barriers remain intact and functional.

Loss of Functionality and Performance Metrics

Monitoring key performance metrics such as switching speed, gate drive current, and saturation voltage can reveal a gradual loss of functionality in IGBT modules. Implementing a comprehensive diagnostic testing strategy is crucial to detect any deviations from established performance norms. According to industry standards, performing routine checks can potentially preemptively identify up to 60% of failures, ensuring that modules operate effectively and efficiently throughout their use.

Prevention Methods for IGBT Module Failures

Advanced Cooling Systems and Thermal Management

Implementing advanced thermal management solutions is essential for mitigating the risk of thermal runaway in IGBT modules. Techniques such as liquid cooling and heat sinks can significantly reduce overheating issues, which are primary culprits of module failure. Efficient heat dissipation methods help in maintaining optimal temperature ranges, thus prolonging the lifespan of IGBT modules. Studies indicate that using advanced cooling systems can reduce the failure rates related to overheating by up to 50%, ensuring better reliability and performance of electronic systems.

Voltage Regulation and Snubber Circuits

Integrating voltage regulation systems and snubber circuits into IGBT modules is a proactive measure against voltage spikes and transients. These components absorb and dissipate excess energy, thereby safeguarding the modules from conditions that could lead to breakdown. This preventive strategy is supported by multiple case studies that demonstrate a significant reduction in failure rates when snubber circuits are employed. Such evidence underscores their effectiveness in ensuring the longevity and stability of IGBT modules in various applications. By incorporating these techniques, electronic device developers can minimize the risk of voltage-induced damage and enhance long-term performance.

Protective Circuitry for Overcurrent Mitigation

Protective circuitry, including the use of fuses and circuit breakers, is vital for mitigating risks associated with overcurrent conditions in IGBT modules. These protective measures are designed to disconnect the module under fault conditions, thereby averting potential damage. Statistics reveal that integrating protective circuit devices diminishes short-circuit failures by nearly 30%. This significant impact underlines the importance of such preventive measures in maintaining the integrity and functionality of the IGBT modules, ensuring their reliability in diverse industrial applications. By implementing protective circuitry, stakeholders can effectively safeguard against overcurrent-induced damages, thereby enhancing module resilience.

Best Practices for IGBT Module Maintenance

Routine Inspection and Diagnostic Testing

Regular inspections and diagnostic testing are the foundation of effective IGBT module maintenance. They ensure the components operate at peak performance and preempt potential issues before they escalate into serious failures. Sophisticated diagnostic tools have emerged as essential instruments in this process, enabling technicians to identify and address faults at an early stage. It is recommended that these inspections occur at predetermined intervals, in line with industry guidelines, to maintain optimal operational conditions and prolong the lifespan of the modules.

Optimal Environmental Conditions for Operation

Ensuring IGBT modules operate within optimal environmental conditions, such as proper humidity and temperature control, is paramount for maintaining their health and efficiency. Both excessive moisture and extreme temperature variations can accelerate degradation, leading to premature failures of the modules. To counteract these risks, the integration of robust climate control systems is advised. Such systems not only help in maintaining the ideal environment but also in enhancing the operational reliability and lifespan of the IGBT modules significantly.

Avoiding Electrical and Mechanical Overloads

Operating IGBT modules within their specified electrical and mechanical limits is crucial to prevent overload situations. Adhering to the operational limits ensures the longevity and optimal performance of these components. Personnel involved in the handling or operations of IGBT modules should be adequately trained to recognize and rectify possible overload scenarios promptly. Research and studies suggest that strict adherence to these operational parameters can lead to a substantial reduction in failure instances, thus promoting efficient and safe use of IGBTs.

Conclusion: Key Strategies for Prolonging IGBT Lifespan

To ensure the longevity of IGBT modules, addressing common failure conditions and implementing preventative measures are paramount. Key strategies include adhering to best practices in maintenance, such as routine inspections and monitoring of environmental conditions. By identifying potential issues early through these practices, businesses can effectively prolong the lifespan of their IGBT modules.

Investment in advanced technologies and regular monitoring plays a crucial role in enhancing operational reliability. For instance, the use of sophisticated diagnostic tools can facilitate real-time condition monitoring, allowing for early detection of wear and impending failures. These proactive steps not only improve performance but also reduce downtime and maintenance costs significantly.

FAQ

What are IGBT modules used for?

IGBT modules are used in power electronics to switch and control electrical power efficiently. They are commonly found in renewable energy systems and electric vehicles.

What causes thermal runaway in IGBT modules?

Thermal runaway is often caused by inadequate cooling systems and poor thermal management, leading to uncontrolled temperature increases.

How can overvoltage stress be mitigated in IGBT modules?

Overvoltage stress can be mitigated using voltage protection mechanisms, including snubber circuits, which absorb and dissipate excess energy.

What are the signs of IGBT module failure?

Signs include overheating, electrical arcing, and loss of functionality. Monitoring performance metrics can also indicate potential failures.