konvertor i Frekuenca

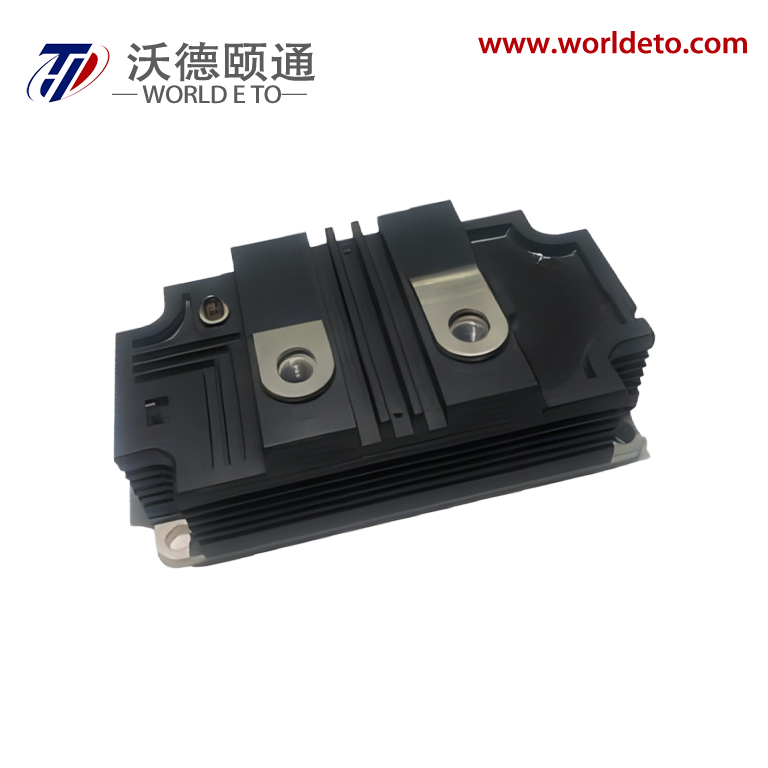

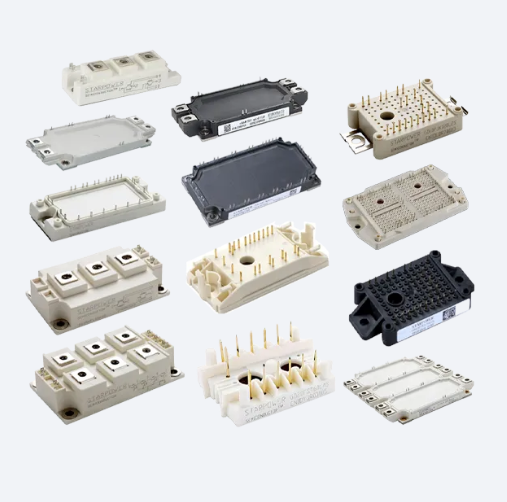

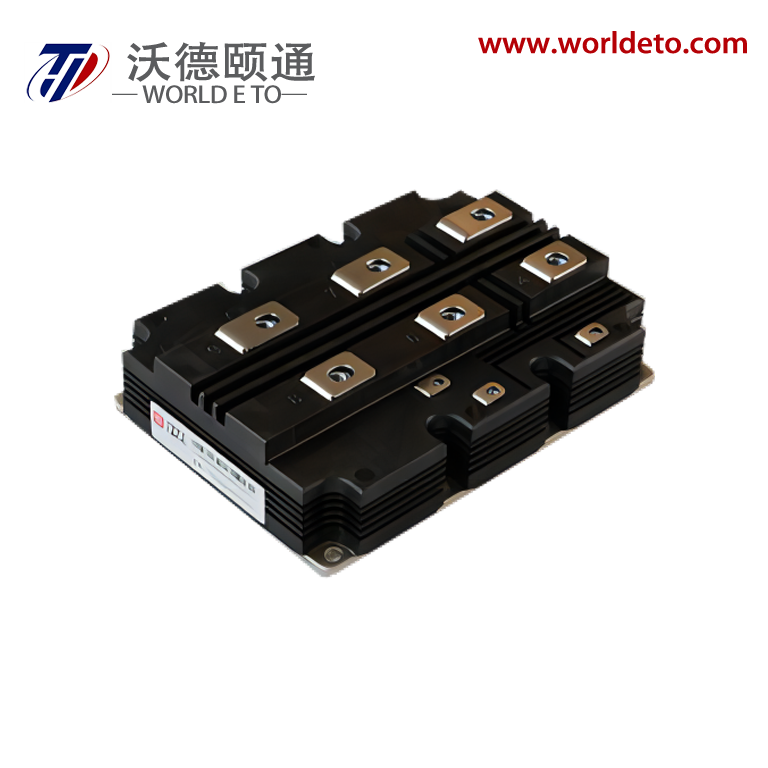

Një ndryshues frekuence është një pajisje elektrike e sofistikuar e projektuar për të kthyer energjinë nga një frekuencë në një tjetër, duke lejuar funksionimin e parezervuar të pajisjeve të ndryshme elektrike nëpër sisteme të ndryshme të energjisë. Kjo pajisje e shumëtë është një komponent kyç në aplikimet industriale moderne, duke ofruar kontroll të saktë mbi daljen e frekuencës elektrike. Në thelbin e saj, ndryshuesi i frekuencës përbëhet nga komponentë elektronikë të avancuar që punojnë së bashku për të modifikuar frekuencën e hyrjes, zakonisht nga frekuencës standarde të rrjetit (50/60 Hz), për të plotësuar kërkesat operative të veçanta. Pajisja përdor teknologji të avancuar elektronike të energjisë, përfshirë raddriftuesit dhe inverterët, për të arritur konvertimin e saktë të frekuencës duke mbajtur të pandryshueshme nivelet e tensionit. Ndryshuesit modernë të frekuencës shpesh përfshijnë sisteme kontrolli digjitale që lejojnë mbikëqyrjen dhe rregullimin në kohë reale të parametrave të daljes, duke siguruar performancën optimale dhe mbrojtjen kundër anomalive elektrike. Këto pajisje gjejnë aplikime të gjera nëpër industri të ndryshme, nga sektorët e prodhimit dhe instalimet testimi deri te sistemet e energjisë së rinovueshme dhe pajisjet laboratorike të specializuara. Teknologjia është zhvilluar për të ofruar eficiencë të përmirësuar, humbje të ulëta të energjisë dhe besueshmëri të përmirësuar, duke e bërë atë një mjet të pazëvendësueshëm për bizneset që kërkojnë kontroll të saktë të frekuencës.