Memilih modul IGBT yang tepat adalah penting untuk inverter tegangan rendah. Komponen-komponen ini secara langsung mempengaruhi kecekapan dan kebolehpercayaan sistem anda. Modul yang sesuai memastikan prestasi optimum, mengurangkan kerugian tenaga, dan meningkatkan ketahanan. Dengan memilih modul yang sesuai, anda boleh mencapai pengurusan terma yang lebih baik dan kestabilan jangka panjang dalam aplikasi inverter anda.

Faktor-faktor utama dalam memilih modul IGBT

Voltan Rating dan Kestabilan

Apabila memilih modul IGBT, anda mesti mempertimbangkan rating voltan. Rating voltan modul harus melebihi voltan maksimum aplikasi anda. Ini memastikan modul beroperasi dengan selamat tanpa pecah. Kestabilan adalah sama pentingnya. Modul yang stabil mengekalkan prestasi yang konsisten walaupun dalam keadaan voltan yang berfluktuasi. Untuk inverter tegangan rendah, memilih modul dengan margin voltan yang sesuai mencegah kegagalan dan memanjangkan umur sistem.

Kapasiti Arus untuk Aplikasi

Kapasiti semasa IGBT modul yang semasa menentukan berapa banyak arus yang boleh ditangani tanpa kepanasan berlebihan. Anda perlu menyamakan penilaian arus modul dengan keperluan aplikasi anda. Sebagai contoh, pemandu motor industri memerlukan kapasiti arus yang lebih tinggi berbanding elektronik pengguna. Memilih modul dengan kapasiti yang tidak mencukupi boleh menyebabkan kepanasan berlebihan dan kecekapan yang berkurangan. Sentiasa sahkan penilaian arus modul untuk memastikan ia memenuhi keperluan sistem anda.

Kelajuan dan Kecekapan Peralihan

Kelajuan pemilihan secara langsung memberi kesan kepada kecekapan IGBT modul. Pemilihan yang lebih pantas mengurangkan kerugian tenaga semasa penukaran kuasa. Ini amat penting untuk aplikasi seperti inverter, di mana kecekapan adalah keutamaan. Anda harus menilai frekuensi pemilihan modul dan memastikan ia sejajar dengan matlamat prestasi sistem anda. Pemilihan yang lebih pantas juga meminimumkan penghasilan haba, meningkatkan kebolehpercayaan keseluruhan.

Pengurusan Terma dan Penyejukan

Pengurusan terma yang berkesan adalah penting untuk mengekalkan prestasi modul IGBT. Modul-modul ini menghasilkan haba semasa operasi, yang boleh merosakkan komponen jika tidak dikelola dengan baik. Anda harus mempertimbangkan modul dengan ciri penyejukan binaan atau reka bentuk sistem anda dengan penyerap haba dan kipas yang mencukupi. Penyejukan yang betul memastikan modul beroperasi dalam had suhu yang selamat, meningkatkan ketahanannya.

Jenis-jenis Modul IGBT

Modul IGBT Tunggal

Modul IGBT tunggal mengandungi satu IGBT dan diod dalam bungkusan yang padat. Modul-modul ini sesuai untuk aplikasi yang memerlukan kawalan kuasa mudah. Anda boleh menggunakannya dalam sistem seperti pemandu motor DC atau inverter kecil. Reka bentuk mudah mereka menjadikannya mudah disepadukan ke dalam litar anda. Modul tunggal juga kos ekonomi, yang menguntungkan untuk projek dengan bajet ketat. Walau bagaimanapun, mereka mungkin tidak menangani tahap kuasa tinggi seberkesanan konfigurasi lain.

Modul IGBT Berganda

Modul IGBT dual menggabungkan dua IGBT dan dua diod dalam unit tunggal. Konfigurasi ini membolehkan anda mencipta litar half-bridge, yang biasa digunakan dalam inverter dan pemandu motor AC. Modul dual menawarkan prestasi yang lebih baik untuk aplikasi kuasa sederhana. Mereka mengurangkan keperluan komponen tambahan, menyederhanakan reka bentuk sistem anda. Anda mungkin menjumpai modul-modul ini dalam pemandu motor industri atau pengubah frekuensi. Reka bentuk ringkas mereka juga membantu menghemat ruang dalam susunan anda.

Modul IGBT Berpelbagai-Tahap

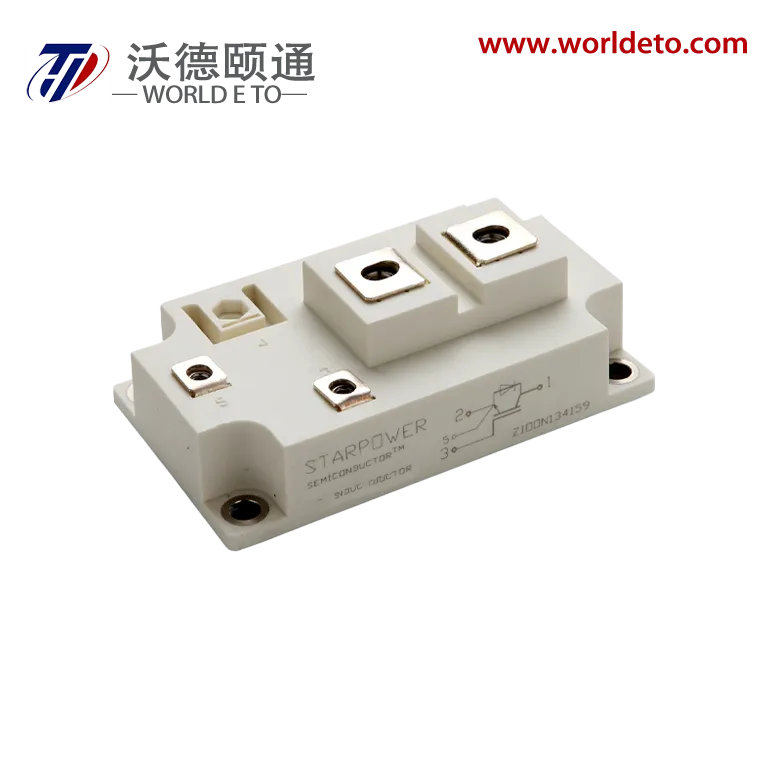

Modul IGBT berpelbagai-tahap direka untuk aplikasi kuasa tinggi. Mereka menggunakan pelbagai IGBT untuk mencipta konfigurasi litar lanjutan, seperti inverter tiga-tahap atau lima-tahap. Modul-modul ini meningkatkan kecekapan dengan mengurangkan kerugian pemilihan dan tekanan voltan pada komponen individu. Anda boleh menggunakannya dalam sistem tenaga terbarukan atau pemandu industri besar. Modul berpelbagai-tahap adalah lebih kompleks tetapi memberikan prestasi yang superior untuk aplikasi yang mencabar.

Perbandingan Konfigurasi

| Pengaturcaraan | Komponen Yang Termasuk | Permohonan | Kelebihan |

| Modul IGBT Tunggal | 1 IGBT + 1 Diode | Penggerak motor DC, inverter kecil | Mudah, kos ekonomi |

| Modul IGBT Berganda | 2 IGBTs + 2 Diodes | Penggerak motor AC, inverter | Padat, prestasi daya sederhana |

| Modul Berperingkat Berbilang | Bilangan IGBTs + Diodes | Tenaga boleh diperbaharui, penggunaan perindustrian | Kecekapan tinggi, kerugian dikurangkan |

Apabila memilih antara konfigurasi ini, pertimbangkan keperluan kuasa dan ketelitian aplikasi anda. Modul tunggal sesuai untuk keperluan asas, manakala modul dua dan berperingkat berbilang menangani tugas yang lebih mencabar.

Kelebihan dan Cabaran Modul IGBT

Kelebihan: Kecekapan dan Serbaguna

Modul IGBT menawarkan kelebihan yang signifikan dalam elektronik kuasa. Kecekapan tinggi mereka meminimumkan kerugian tenaga semasa penukaran kuasa. Ini menjadikannya ideal untuk aplikasi seperti inverter dan pemandu motor, di mana simpanan tenaga adalah kritikal. Anda juga boleh mengambil manfaat daripada keluwesan mereka. Modul-modul ini menangani julat tegangan dan arus yang luas, menjadikannya sesuai untuk pelbagai aplikasi, termasuk sistem tenaga boleh diperbaharui, kenderaan elektrik, dan automatik industri.

Satu lagi kelebihan utama adalah reka bentuk kompak mereka. Modul IGBT membolehkan anda mencipta sistem yang lebih kecil dan lebih cekap tanpa mengorbankan prestasi. Kelajuan pertukaran pantas mereka meningkatkan tanggapan sistem dan ketepatan, yang penting dalam aplikasi seperti penukar frekuensi dan pemula lembut.

Cabaran: Penyerakan Haba dan Kos

Walaupun mempunyai kelebihan, modul IGBT hadir dengan cabaran. Penyerakan haba adalah satu perkara utama. Modul ini menghasilkan haba yang ketara semasa beroperasi, yang boleh merosakkan komponen jika tidak dikelola dengan berkesan. Anda mesti melaksanakan penyelesaian penyejukan yang betul untuk mengekalkan suhu operasi yang selamat.

Kos adalah cabaran yang lain. Modul IGBT berkualiti tinggi boleh menjadi mahal, terutamanya untuk konfigurasi maju seperti modul pelbagai paras. Ini mungkin meningkatkan kos keseluruhan projek anda. Walau bagaimanapun, manfaat jangka panjang sering melebihi pelaburan awal.

Penyelesaian untuk Mengatasi Cabaran

Anda boleh menangani penyerakan haba dengan menyertakan sistem pengurusan terma yang cekap. Gunakan penyerap haba, kipas penyejuk, atau penyejukan cecair untuk mengekalkan modul dalam had suhu yang selamat. Memilih modul dengan ciri penyejukan binaan dalaman juga boleh memudahkan reka bentuk anda.

Untuk mengurus kos, nilai keperluan spesifik aplikasi anda. Elakkan melampau dalam menetapkan voltan atau penilaian arus modul. Bekerja rapat dengan pengeluar boleh membantu anda mencari penyelesaian berkos rendah tanpa mengorbankan kualiti. Dengan menyeimbangkan prestasi dan bajet, anda boleh memaksimumkan nilai pelaburan anda dalam modul IGBT.

Memilih modul IGBT yang betul memastikan inverter anda beroperasi dengan cekap dan boleh dipercayai. Tumpukan pada voltan, arus, dan frekuensi penukaran untuk sesuai dengan aplikasi anda. Jelajahi modul tunggal, dua, atau pelbagai tahap berdasarkan keperluan kuasa. Nilai keperluan sistem anda, utamakan kecekapan, dan rujuk kepada pengeluar untuk penyelesaian tersuai. Pendekatan ini menjamin prestasi optimum dan kejayaan jangka panjang.