Sie verlassen sich täglich auf Isolierte-Gate-Bipolar-Transistoren (IGBTs), ob Sie es bemerken oder nicht. Diese Geräte versorgen elektrische Fahrzeuge, erneuerbare Energiesysteme und industrielle Automatisierung mit Energie. Ihre Fähigkeit, hohe Spannungen und Ströme zu bewältigen, macht sie für energieeffiziente Systeme unerlässlich. Neue Technologien im IGBT-Design verbessern die Leistung weiterhin, um sicherzustellen, dass Industrien den modernen Anforderungen gerecht werden.

Neue Technologie in IGBT: Ein Überblick

Was ist IGBT und welche Kernfunktionalität hat es?

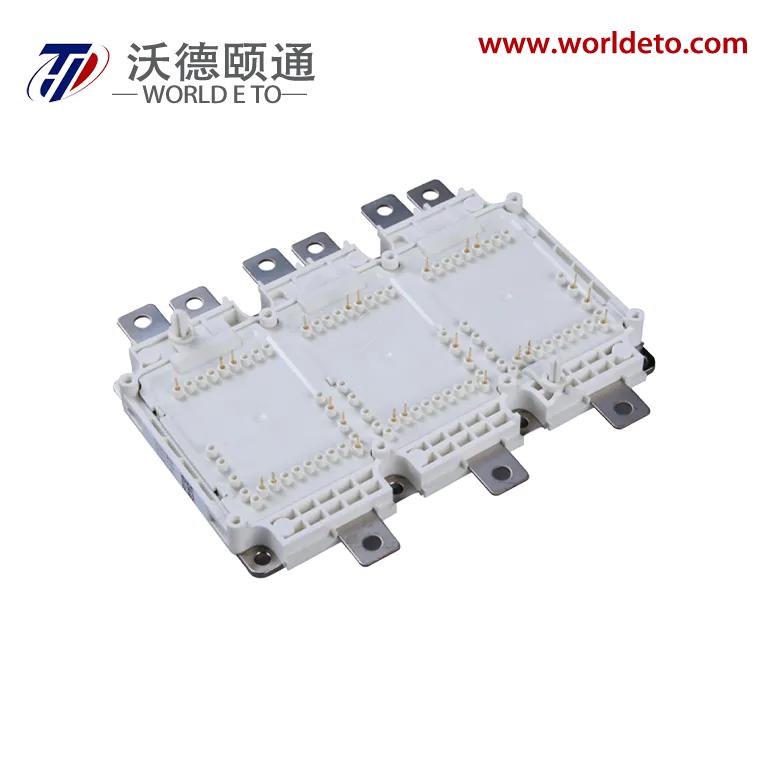

Sie fragen sich vielleicht, was IGBT in der modernen Elektronik so essenziell macht. Isolierte-Gate-Bipolar-Transistoren (IGBTs) kombinieren die besten Eigenschaften zweier Technologien: die Hochgeschwindigkeitsumschaltung von MOSFETs und das starke Stromdurchlassvermögen von BJTs. Diese Hybridgestaltung ermöglicht es dem IGBT, als Schalter zu fungieren und den Stromfluss in Schaltkreisen zu steuern. Es arbeitet, indem es über ein Gatterterminal den Strom zwischen Kollektor undEmitter regelt. Diese Fähigkeit, hohe Spannungen und Ströme zu bewältigen, macht den IGBT zu einem Eckpfeiler in der Leistungselektronik.

Hauptvorteile des IGBT in der Leistungselektronik

IGBT bietet mehrere Vorteile, die es unentbehrlich machen. Seine hohe Effizienz reduziert Energieverluste während des Betriebs. Auf ihn kann bei Anwendungen vertraut werden, die hohe Schaltfrequenzen erfordern, wie Umrichter und Frequenzumformer. IGBT ermöglicht auch kompakte Designs, was hilfreich ist, um kleinere und effizientere Geräte zu erstellen. Seine Fähigkeit, hohe Leistungsstufen zu bewältigen, gewährleistet Zuverlässigkeit in anspruchsvollen Umgebungen wie industrieller Automatisierung oder Erneuerbare-Energiesystemen.

Die Rolle des IGBT in energieeffizienten und hochleistungsfähigen Anwendungen

Energieeffizienz ist ein kritischer Fokus in der heutigen Welt. IGBT spielt eine entscheidende Rolle bei der Erreichung dieses Ziels. Es minimiert Energieverluste in Systemen wie AC-Motortreiber, DC-Motortreiber und Softstarter. Man findet IGBT auch in Anwendungen der erneuerbaren Energie, wo es Solarenergie oder Windenergie in nutzbare Elektrizität umwandelt. Seine hohe Schaltfrequenz und seine Fähigkeit, große Ströme zu verarbeiten, machen es ideal für hochleistungsfähige Anwendungen, wodurch sichergestellt wird, dass Systeme reibungslos und effizient arbeiten.

Technologische Fortschritte in IGBT-Modulen

Der Wechsel zu Siliciumcarbid (SiC) und Galliumnitrid (GaN)

Sie haben wahrscheinlich bemerkt, wie Industrien höhere Effizienz und Leistung von Leistungselektronik verlangen. Diese Nachfrage hat zu einem Wechsel zu Materialien wie Siliciumkarbid (SiC) und Galliumnitrid (GaN) in IGBT-Modulen geführt. Diese Materialien übertrumpfen die traditionelle Siliziumtechnologie durch geringere Energieverluste und höhere Wärmeleitfähigkeit. SiC-basierte IGBT-Module verarbeiten höhere Spannungen und Ströme, was sie für Anwendungen wie Umrichter und Gleichstrommotorantriebe ideal macht. GaN hingegen zeichnet sich durch Hochfrequenzschaltung aus, was kompakte Designs und Verbraucherelektronik vorantreibt.

Prozessoptimierungen für höhere Effizienz und Zuverlässigkeit

Sie könnten sich fragen, wie IGBT-Module weiterentwickelt werden. Prozessoptimierungen spielen eine Schlüsselrolle bei der Verbesserung ihrer Leistung. Hersteller verwenden nun fortgeschrittene Fertigungstechniken, um Fehler zu reduzieren und die Haltbarkeit von IGBT-Modulen zu verbessern. Diese Optimierungen ermöglichen es den Modulen, bei höheren Schaltfrequenzen zu betreiben, ohne überzuheizen. Verbesserte Designs sorgen außerdem für einen besseren Stromfluss und Spannungsabwicklung, was die Zuverlässigkeit in anspruchsvollen Anwendungen wie AC-Motortreiber und Softstarter erhöht. Mit diesen Fortschritten können Sie erwarten, dass IGBT-Module auch in strengen Umgebungen konsistente Leistung liefern.

Hochfrequenzschaltung für moderne Anwendungen

Moderne Anwendungen verlangen nach schnelleren und effizienteren Stromumwandlungen. Hochfrequenzschaltung in IGBT-Modulen deckt dieses Bedürfnis ab. Sie werden diese Funktion insbesondere in Systemen wie Frequenzumrichtern und Erneuerbare-Energie-Wechselrichtern nützlich finden. Hochfrequenzschaltung reduziert Energieverluste und ermöglicht eine reibungslosere Betriebsweise von Geräten. Sie fördert auch die Miniaturisierung, wodurch Sie kompakte Systeme entwerfen können, ohne dabei Leistungseinbußen zu erleiden. Diese neue Technologie stellt sicher, dass IGBT-Module weiterhin an der Spitze der Innovation stehen, von der industriellen Automatisierung bis hin zu Elektrofahrzeugen alles antreibend.

Neue Anwendungen der IGBT-Technologie

Industrielle Automatisierung und Robotik

Sie sehen IGBT-Module, die Innovation in der industriellen Automatisierung und Robotik vorantreiben. Diese Module steuern AC-Motorantriebe und Frequenzumformer, um eine präzise Funktionsweise von Maschinen zu gewährleisten. In der Robotik ermöglicht IGBT-Technologie eine gleichmäßige Bewegungssteuerung durch die Verwaltung der Schaltfrequenz von IGBT-Geräten. Dadurch wird sichergestellt, dass Roboter Aufgaben mit Genauigkeit und Effizienz ausführen. Fabriken verlassen sich auf IGBT-Module zur Betriebsweise von Softstartern, die Verschleiß und Verschleifung von Motoren beim Start reduzieren.

Verbraucherelektronik und Startseite ## Geräte

IGBT-Module spielen eine Schlüsselrolle bei der Effizienzsteigerung Ihrer Haushaltsgeräte. Geräte wie Klimaanlagen, Waschmaschinen und Kühlschränke verwenden mit IGBT-Technologie betriebene Wechselrichter. Diese Wechselrichter regulieren die Spannung der IGBT-Module, um den Energieverbrauch zu optimieren. Zum Beispiel passt eine Klimaanlage mit einem auf IGBT basierenden Wechselrichter ihre Kühlleistung je nach Raumtemperatur an, wodurch Strom eingespart wird. Sie profitieren außerdem von einer leiseren Betriebsart, da IGBT-Module das Geräusch durch eine gleichmäßigere Energieübertragung reduzieren.

Hochgeschwindigkeitsbahnen und Luftfahrtanlagen

Schnellzüge und Luftfahrtanlagen erfordern zuverlässige und effiziente Power-Elektronik. IGBT-Module erfüllen diese Anforderungen, indem sie hohe Ströme und Spannungen verarbeiten. In Hochgeschwindigkeitszügen steuern sie Gleichstrommotorantriebe und Umrichter, um ein gleichmäßiges Beschleunigen und Bremsen sicherzustellen. Luftfahrtanlagen nutzen IGBT-Technologie zur Verwaltung der Stromversorgung und Antriebssysteme. Die hohe Schaltfrequenz von IGBT-Geräten ermöglicht es diesen Systemen, präzise und zuverlässig zu arbeiten.

Sie haben gesehen, wie Fortschritte bei IGBT-Modulen Branchen verändern. Höhere Schaltfrequenzen, verbesserte Thermomanagement und kompakte Designs machen diese Geräte unentbehrlich. Ihre Rolle in Wechselstrommotorantrieben, Umrichtern und Erneuerbare-Energie-Systemen unterstreicht ihre Bedeutung für Nachhaltigkeit. Bis 2025 können Sie erwarten, dass IGBT-Technologie Innovationen vorantreibt und weltweit effiziente und zuverlässige Stromlösungen ermöglicht.