IGBT modules play a vital role in welding machines by controlling power flow with precision. Choosing the right module ensures consistent performance and energy efficiency. You must evaluate voltage, current, and thermal management to match your machine's requirements. Prioritizing reliability and long-term value over initial cost guarantees optimal results.

Understanding IGBT Modules

What Are IGBT Modules?

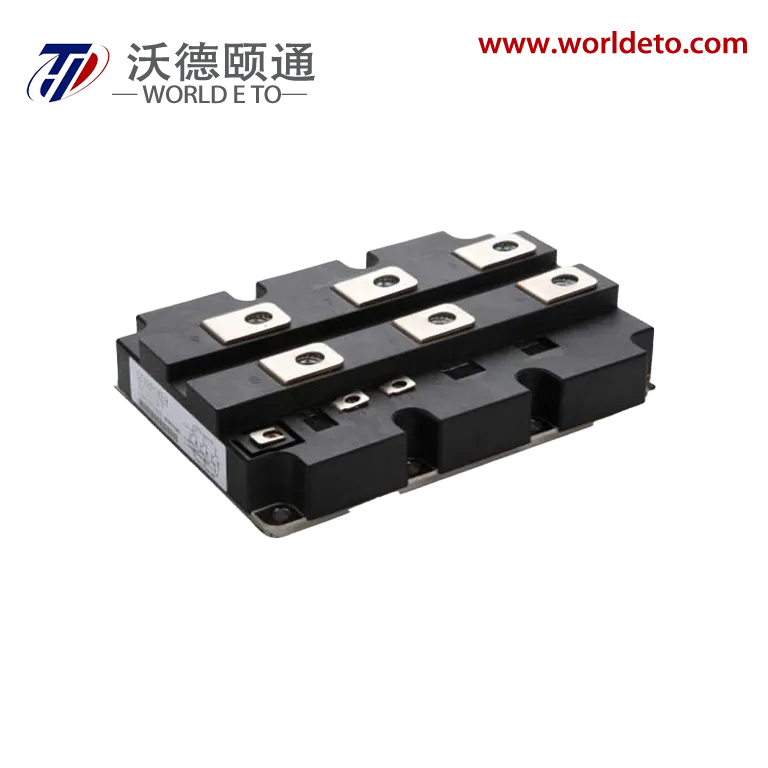

IGBT modules, or Insulated Gate Bipolar Transistor modules, are advanced semiconductor devices that combine the benefits of both MOSFETs and BJTs. These modules act as electronic switches, enabling efficient control of high voltage and current levels in various applications. They are designed to handle significant power loads while maintaining fast switching speeds, making them ideal for industrial equipment.

Each IGBT module consists of multiple IGBT chips and diodes integrated into a single package. This design ensures compactness and simplifies installation. You will find these modules in systems requiring precise power management, such as motor drives, renewable energy systems, and welding machines. Their ability to operate at high efficiency while minimizing energy loss makes them a cornerstone of modern power electronics.

Why Are IGBT Modules Essential for Welding Machines?

Welding machines rely on IGBT modules to regulate power delivery during operation. These modules ensure stable and consistent energy flow, which is critical for producing high-quality welds. Without them, achieving the precision and control required for complex welding tasks would be challenging.

IGBT modules also enhance the energy efficiency of welding machines. By reducing power loss during switching, they help lower energy consumption and operating costs. Additionally, their compact design allows you to build lightweight and portable welding machines without compromising performance. Their durability ensures reliable operation even under demanding conditions, making them indispensable for industrial and commercial welding applications.

Key Factors in Selecting IGBT Modules

Voltage and Current Ratings

You must evaluate the voltage and current ratings of IGBT modules to ensure compatibility with your welding machine. The voltage rating should exceed the maximum voltage your machine operates at to prevent breakdowns. Similarly, the current rating must align with the peak current demands of your welding process. Selecting a module with insufficient ratings can lead to overheating or failure during operation.

Switching Speed and Efficiency

Switching speed directly impacts the efficiency of IGBT modules. Faster switching reduces energy loss, improving overall performance. However, excessively high switching speeds may increase electromagnetic interference (EMI). You should aim for a balance between speed and efficiency to optimize your welding machine's performance.

Thermal Management and Heat Dissipation

Effective thermal management is crucial for maintaining the longevity of IGBT modules. Poor heat dissipation can lead to overheating and reduced efficiency. Look for modules with advanced cooling features, such as integrated heat sinks or thermal pads. Proper thermal management ensures stable operation even under heavy workloads.

Reliability and Durability

Durability is essential for welding machines operating in demanding environments. Choose IGBT modules with robust designs and proven reliability. Modules with high-quality materials and protective features, such as short-circuit protection, offer better long-term performance.

Compatibility with Welding Machine Design

Ensure the IGBT modules you select integrate seamlessly with your welding machine's design. Consider factors like physical dimensions, connection interfaces, and control requirements. Compatibility minimizes installation challenges and enhances operational efficiency.

Cost vs. Performance Trade-offs

While cost is a significant factor, prioritize performance and reliability over initial savings. Investing in high-quality IGBT modules reduces maintenance costs and downtime in the long run. Evaluate the total cost of ownership to make an informed decision.

Performance Considerations for IGBT Modules

Balancing Switching Speed and Power Loss

Switching speed plays a critical role in the performance of IGBT modules. Faster switching reduces energy loss during transitions, which improves efficiency. However, higher speeds can increase switching losses and generate more heat. You need to find the right balance between speed and power loss to optimize your welding machine's performance. Evaluate the switching frequency of the module and match it to your machine's operational requirements. This ensures efficient energy use without compromising reliability.

Effective Thermal Management Solutions

Thermal management is essential for maintaining the stability and lifespan of IGBT modules. Excessive heat can degrade performance and lead to premature failure. You should prioritize modules with advanced cooling features, such as integrated heat sinks or liquid cooling options. Proper ventilation within the welding machine also helps dissipate heat effectively. Regularly monitor the module's operating temperature to prevent overheating and ensure consistent performance.

Short Circuit Withstand Capability

Welding machines often operate in demanding conditions, where short circuits can occur. IGBT modules with robust short circuit withstand capabilities protect your equipment from damage. Look for modules designed to handle high fault currents for a specified duration. This feature ensures the module can survive unexpected electrical faults without failure. Incorporating this capability enhances the overall safety and reliability of your welding machine.

Choosing the right IGBT module ensures your welding machine operates efficiently and reliably. Focus on voltage, current, and thermal management to match your system's needs. Avoid prioritizing cost over long-term performance. Consult industry experts and test modules thoroughly before finalizing your choice. This approach guarantees optimal results and minimizes future issues.