IGBT modules play a vital role in high voltage frequency converters by enabling efficient power switching and control. Choosing the right module ensures optimal performance, reliability, and energy efficiency. You must evaluate critical factors like voltage, current, and thermal management to make an informed decision. Always choose IGBT modules that align with your system's requirements.

Key Factors to Choose IGBT Modules

Voltage and Current Ratings

When selecting an IGBT module, you must evaluate its voltage and current ratings. The voltage of IGBT modules should exceed the maximum voltage your application will encounter. This ensures the module can handle voltage spikes without damage. Similarly, the IGBT current rating must align with your system's load requirements. For instance, in applications like frequency converters or soft starters, underestimating these ratings can lead to overheating or failure. Always choose IGBT modules with a safety margin to accommodate unexpected surges.

Switching Frequency

The switching frequency of IGBT modules determines how quickly they can turn on and off. Higher frequencies improve performance and reduce noise in systems like inverters or AC motor drives. However, they also generate more heat, which can affect efficiency. You need to balance the switching frequency with your system's thermal management capabilities. For high-speed applications, prioritize modules designed for efficient operation at elevated frequencies.

Thermal Management

Effective thermal management is crucial for maintaining the reliability of IGBT modules. Heat generated during operation can degrade performance or shorten the module's lifespan. Look for modules with advanced cooling features, such as integrated heat sinks or optimized packaging. In high-power systems like DC motor drives, proper heat dissipation ensures stable operation. Evaluate your system's cooling capacity before finalizing your choice.

Reliability and Durability

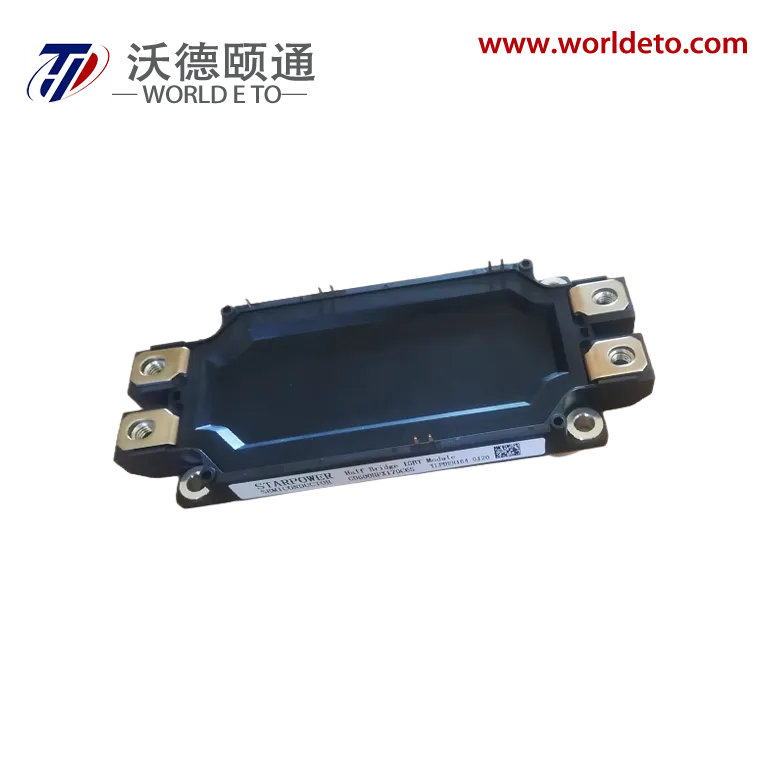

Durability is a key factor when you choose IGBT modules for demanding applications. Modules with robust construction and high-quality materials withstand harsh conditions and prolonged use. For industrial systems like frequency converters, reliability ensures uninterrupted operation. Check for certifications or test results that validate the module's performance under stress.

System Compatibility

Your IGBT module must integrate seamlessly with your existing system. Consider factors like physical dimensions, control interfaces, and electrical characteristics. For example, in an inverter or soft starter, mismatched modules can cause inefficiencies or malfunctions. Always verify compatibility with your system's design and requirements.

Practical Tips for Choosing IGBT Modules

Interpreting Manufacturer Specifications

Manufacturer specifications provide essential details about IGBT modules. You should carefully review these documents to understand the module's voltage, current, and thermal ratings. Pay attention to the maximum voltage and current values, as these determine the module's suitability for your application. Look for switching frequency data to ensure the module can meet your system's performance requirements.

Examine the thermal resistance and cooling requirements outlined in the datasheet. These factors help you assess whether the module can handle the heat generated during operation. Some manufacturers also include graphs or charts showing performance under different conditions. Use this information to predict how the module will behave in your system. By thoroughly analyzing these specifications, you can confidently choose IGBT modules that align with your needs.

Consulting Industry Experts

Industry experts can provide valuable insights when selecting IGBT modules. These professionals have experience with various applications, including frequency converters, inverters, and motor drives. They can help you identify modules that meet your system's unique requirements.

You should seek advice from engineers, technical consultants, or manufacturers' representatives. Share your system's specifications and operational goals with them. Their recommendations can save you time and prevent costly mistakes. Consulting experts ensures you make informed decisions and enhances the reliability of your final choice.

Testing and Prototyping

Testing and prototyping are critical steps in the selection process. Before finalizing your decision, you should test the IGBT module in a controlled environment. This allows you to evaluate its performance under real-world conditions.

Set up a prototype system that mimics your application's operating parameters. Monitor the module's behavior, including its thermal performance, switching efficiency, and reliability. Testing helps you identify potential issues and ensures the module meets your expectations. Prototyping also provides an opportunity to fine-tune your system for optimal performance. By investing time in testing, you reduce the risk of failures and improve overall system efficiency.

Choosing the right IGBT module ensures your high voltage frequency converter operates efficiently and reliably. Focus on key factors like voltage and current ratings, switching frequency, thermal management, reliability, and compatibility. Thoroughly evaluate specifications and consult experts to make informed decisions. This approach enhances system performance and minimizes risks in applications like inverters or motor drives.